Cold-applied liquid roofing systems are renowned for their durability, safety, and seamless waterproof protection, making them one of the most popular choices for flat roofs in the UK. However, like any roofing system, they must be installed and maintained correctly to perform at their best.

Even the most advanced liquid waterproofing systems can develop issues if surface preparation, application, or curing are mishandled. In this guide, we’ll explore the most common problems associated with cold-applied roofs, and more importantly, how to avoid them altogether.

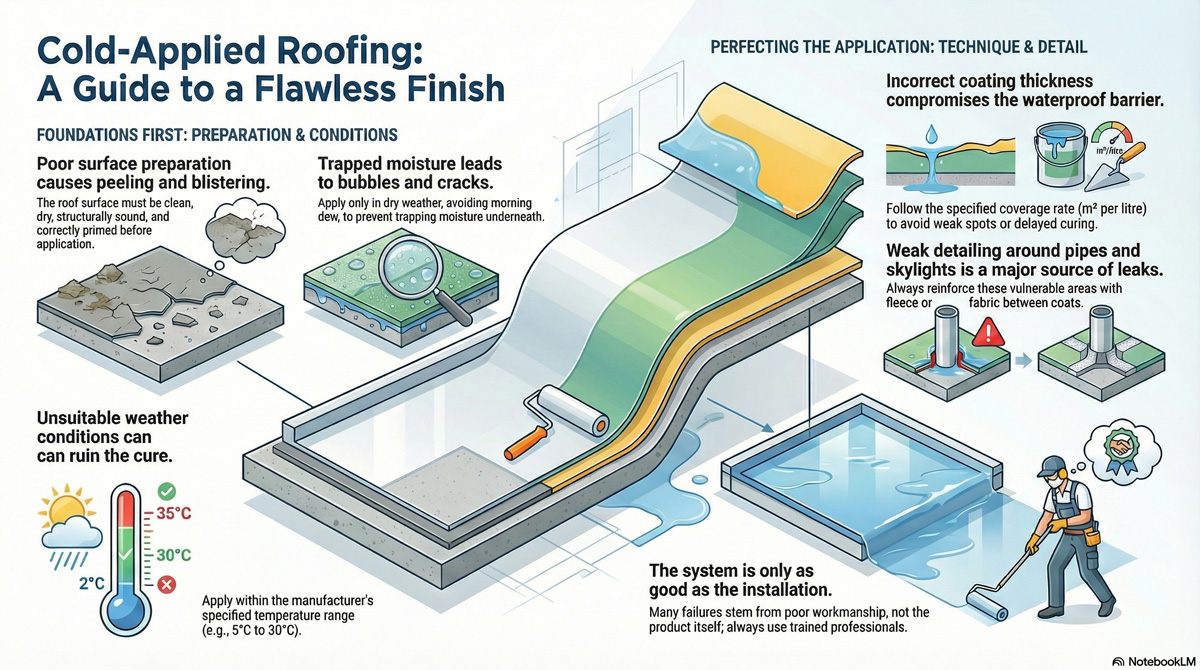

Poor Surface Preparation

The Problem:

A successful cold-applied roof relies on strong adhesion between the liquid membrane and the substrate. If the surface is dirty, damp, or contaminated with dust, oil, or loose debris, the membrane may fail to bond properly, leading to blistering or delamination over time.

How to Avoid It:

- Ensure the substrate is clean, dry, and structurally sound before application.

- Repair cracks, splits, or damaged areas before priming.

- Use the manufacturer’s recommended primer for the specific surface material (concrete, asphalt, timber, metal, etc.).

- Carry out a bond test on small sections if unsure about surface compatibility.

Moisture and Trapped Water

The Problem:

Cold-applied systems can trap moisture beneath the coating if the substrate isn’t completely dry or if condensation forms during application. This can lead to blistering, bubbling, or micro-cracking, particularly when temperatures fluctuate.

How to Avoid It:

- Apply the system only in dry weather and on a dry substrate.

- Avoid early morning applications when dew or condensation may be present.

- Use moisture-tolerant primers when working on older or porous surfaces.

- Follow the manufacturer’s humidity and temperature guidelines precisely.

Uneven or Insufficient Coating Thickness

The Problem:

Applying too thin a layer of liquid waterproofing can compromise durability, while uneven coverage may leave weak spots that allow water ingress. Over-application, on the other hand, can delay curing and trap solvents.

How to Avoid It:

- Always follow the specified coverage rate (in m² per litre) provided by the manufacturer.

- Use reinforcement fabric where required to achieve uniform thickness.

- Apply the liquid in multiple thin coats rather than one thick layer.

- Inspect the surface after curing to ensure consistent coverage and finish.

Inadequate Detailing Around Upstands and Penetrations

The Problem:

Areas such as upstands, outlets, skylights, and pipe penetrations are particularly vulnerable to leaks if not properly detailed. Incorrect application around these features can result in water tracking beneath the membrane.

How to Avoid It:

- Reinforce all detail areas with fleece or fabric between coats.

- Apply liquid coating vertically up upstands to ensure full encapsulation.

- Use compatible sealants and trims recommended by the manufacturer.

- Always finish details before applying the main field area.

Curing and Weather Conditions

The Problem:

Cold-applied systems cure chemically, and temperature and humidity play a crucial role. If applied in unsuitable conditions (too cold, too damp, or too windy), curing may be delayed, resulting in tacky surfaces, reduced adhesion, or premature wear.

How to Avoid It:

- Apply between 5°C and 30°C, depending on product specification.

- Avoid applying in rain or high humidity.

- Protect the roof from foot traffic until full curing is achieved.

- Use fast-curing PMMA systems for time-sensitive projects or variable UK weather.

Ignoring Manufacturer Guidelines

The Problem:

Every cold-applied product has its own technical data sheet specifying primers, curing times, coverage rates, and compatible substrates. Skipping steps or using non-approved products can invalidate warranties and lead to premature failure.

How to Avoid It:

- Always follow the manufacturer’s full installation guide.

- Use approved accessories and reinforcement materials.

- Ensure installers are trained or certified for the chosen system.

Lack of Regular Maintenance

The Problem:

Even the best roofing systems need occasional care. Neglecting maintenance can allow debris buildup, blocked outlets, or small defects to go unnoticed potentially leading to costly repairs.

How to Avoid It:

- Schedule annual inspections to catch early signs of wear.

- Keep roof drains, gutters, and outlets free from leaves and debris.

- Promptly repair any small punctures or damage to prevent escalation.

- Document inspections to maintain warranty coverage.

The Importance of Professional Installation

Many cold-applied roofing issues stem not from the system itself, but from poor workmanship or lack of experience. Partnering with a specialist contractor ensures:

- Correct product selection for your roof type

- Proper surface preparation and detailing

- Consistent application thickness

- Full compliance with manufacturer and UK safety standards

Astral Roofing’s trained installers have extensive experience with leading UK systems, ensuring long-lasting, flawless results on every project.

Conclusion

Cold-applied liquid roofing is one of the most reliable, adaptable, and safe waterproofing systems available for flat roofs but it’s only as good as the installation behind it.

By following proper preparation and curing procedures, using certified materials, and conducting regular maintenance, property owners can enjoy decades of leak-free performance.

When installed correctly, a liquid-applied roof doesn’t just protect your property – it provides peace of mind, safety, and long-term value.

Get in Touch

Thinking about a cold-applied liquid roofing system for your property?

At Astral Roofing, we use only UK-approved, flame-free waterproofing systems installed by experienced professionals. Whether you need a new installation, refurbishment, or leak repair, we’ll ensure your roof performs flawlessly for years to come.

Request your free roofing quote today and get expert advice tailored to your building and budget.